● Application scope : cotton, chemical fiber filament and differential fiber : 6S-120S (300D-40D)

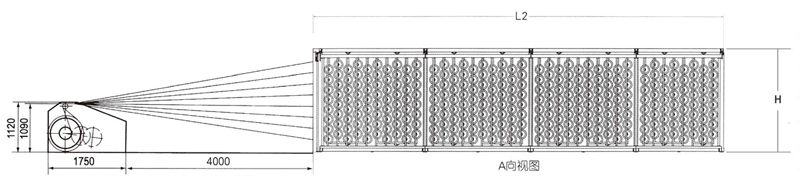

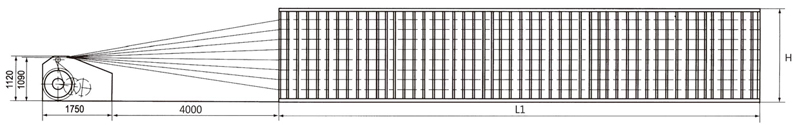

● Warping breadth : 1600mm 1800mm 2000mm 2200mm 2400mm 2600mm 2800mm

● Warping speed : ≤1200m/min

● Winding diameter : 800mm 1000mm 1200mm

● Warpbeam braking distance : ≤2.5m (600m/min)

● Length calculating accuracy : ≤0.2%

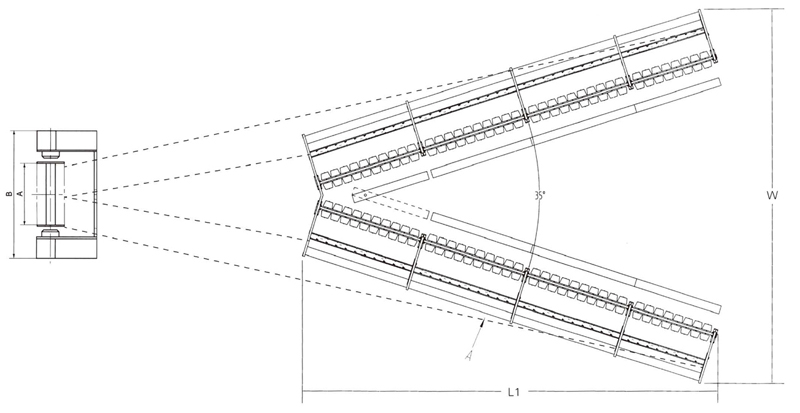

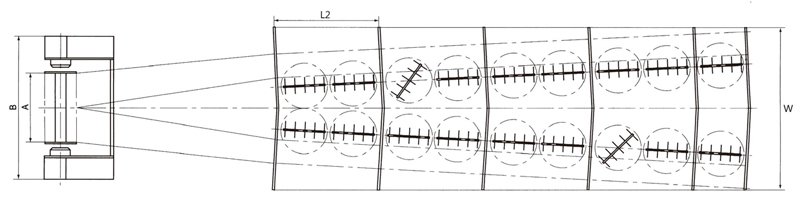

● Track parallel track pressurization principles are used for warping

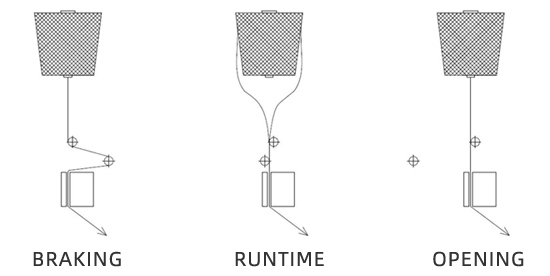

● Warpbeam and compression roller use clampbrakes, the high-pressure brake liquid generated by gas-liquid pressurization brakes.

● The motor directly drives the main shaft, the brake clampdirectly brakes by acting on the main shaft.

● The screen of the warping machine can set the main process parameters, such as ends in warp, length, speed, end breakage rate, shaft and daily output, etc., at the same time, it can modify, display data in real time and save.

● The touch screen controls the opening and closing of creel yarn gripper and pretension rod.

● The touch screen adjusts the tension of the piece of yarn on the creel in real time.

● The touch screen can adjust the left and right quantitative swing of the regulating expansion reed, the density of the dent, alignment of the piece of yarn and warpbeam and achieve automatic rise and fall fluctuation. Cleaning blowing of the expansion reed can be set at any frequency.

● A pair of prolonged expansion reed can cover all the required application seam heading.

● Anti-warpwinding device is designed.

● Cord roller yarn breaking alarm device is designed.

● Handwheel can directly control the alignment of the warpbeam and the compression roller.

● New fully-closed organic glass shield is used.

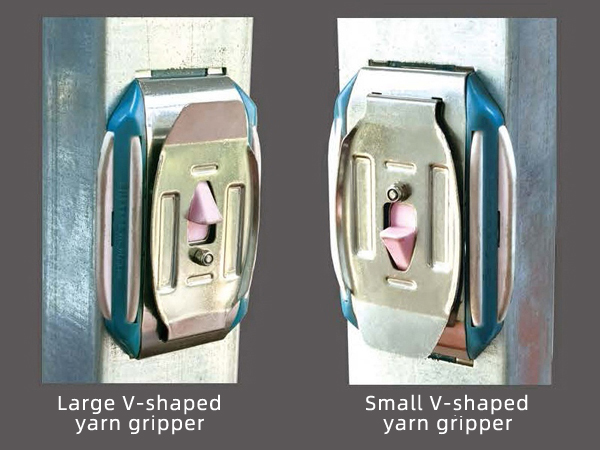

● Creel-type V-shape (large, with an angle of 35°) (small, with an angle of 6°)

● The seam heading of the creel is designed in accordance with the requirements of the users.

● The spindle pitch is designed in accordance with the requirements of the users.

● Yarn gripper uses grindable aluminum oxide ceramics. Mirror finished stainless steel materials are made by the process of precise punching.

● The automatic stopof single yarn photovoltaic broken ends is overall designed with the yarn gripper.

● The machine head and creel use 485 bus communication, achieving monitoring of total seam heading. The machine head PLC is equipped with DP-bus port to achieve computer network management.

● The inside of large V-shaped yarn gripper is designed with a cleaning device for two blow-off nozzles. The blowing frequency can be adjusted and set in real time. No dust or cotton will be accumulated inside the yarn gripper. The opening of the small V-shaped yarn gripper is downward, facilitating automatic falling-off of flying cotton.

● Chained creeling and rotating frame creeling are optional.

● Electric yarn cutting device is designed.

0086-510-86277981

0086-510-86277981